Importance of a Crane Signal Person

During the operation of a crane, the crane needs more than just a crane operator. While the crane operator holds most of the responsibility for the control of machinery, the other person that is also vital in a crane operation is a crane signal person.

In this article, we will dive through the various questions regarding a crane signal person. Does crane signal person necessary for the crane operation? What are their responsibilities? We have all the answers.

What is a Crane Signal Person?

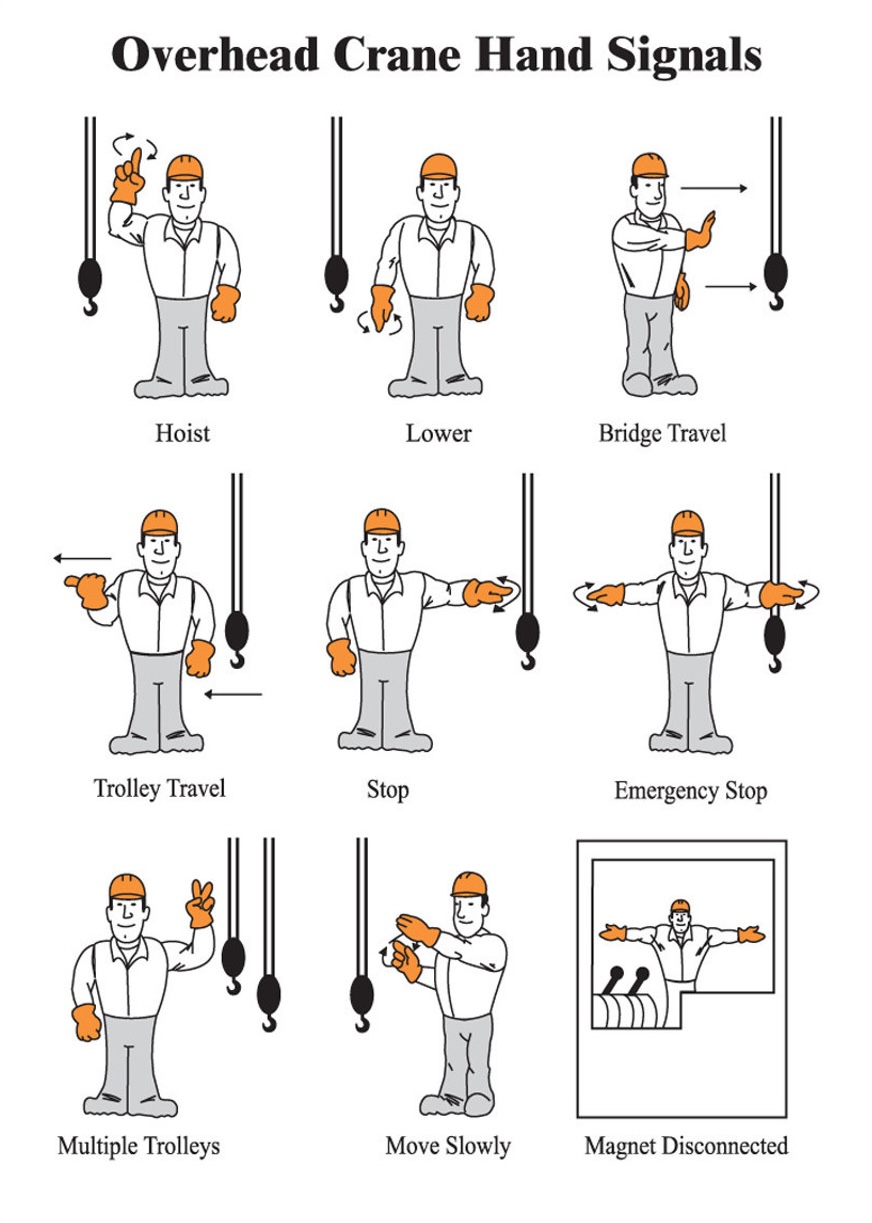

A crane signal person is a trained professional responsible for communicating with the crane operator through standardized crane hand signals or audio signals via radio and other devices. Signal person guides the movement of the crane, including operating the boom, lifting and lowering loads, stopping the operation, and repositioning the crane as needed. They has to quickly assess the situation in case of emergency.

By communicating directions accurately, a skilled crane signal person significantly enhances both the safety and efficiency of crane operations, helping to prevent accidents and ensuring that tasks are completed successfully.

In addition to their communication responsibilities, the crane signal person also plays a crucial role in coordinating with other crews on-site including the crane operator, crane rigger, lift director and more.

What is a Crane Signal Person Responsibility?

A crane signal person holds many responsibilities, ensuring the accurate communication and safety for the operation.

- While the crane operator can see the surrounding by themselves through the cab, a signal person often has clearer point of view from outside the crane, making them assessing the environment better

- Understanding every signal related to a crane operation, Whether it is hand signal, voice command or radio signal.

- Interpreting and relaying the signals to the crane operator accurately throughout the operation

- Ensuring the safety during the lifting operation by monitoring the surrounding

- Communicating with ground personnel and ensure that everyone is in a safe distance from a crane

- Inspecting the surrounding for the obstacles and guiding the crane operator to avoid them

- Remaining alert at all time and be prepared to relay halt or stop signal to avoid safety risk

- Always stays updated with safety regulation and other information related to operating a crane

- In the case of multiple crans are operating at the same time, a signal person play a key role to prevent conflict between each machinery

Is a Trained Crane Signal Person Important?

Does every construction site need a crane signal person? The answer is yes. The importance of their role cannot be overlooked. The signal person has a broader view of the surroundings and they can assess the situation and relay the signals accurately. Their responsibility helps prevent accidents, reduces the risk of property damage and ensures the safety of the workers while the crane operators carry out the task with full potential, increasing the efficiency of the operation.

Additionally, crane signal person has to keep up with the regulation and safety standard, which could further improve the safety and operation process.

Apart from crane signal person, there are other duties that are vital in crane operation. For example,

- Crane supervisor or site supervisor – Their responsibility is to oversee all of the operation including, planning, safety inspection, training the workers, and much more, to ensure that the operation goes smoothly and within the timeline.

- Crane rigger – They attached the load to a crane, secured it and make sure that the transportation goes along the plan and safe

- Lift director – They oversee the lifting operation and ensure every crew safety. They also inspected the area preparation before the crane operation started.

- Crane operator – Operating a crane is their main duty, They must be aware of the surrounding with the help of signal person while operating a crane to lift and move materials around

Safety Tips

Other than having a crane signal person on the site, there are also tips that could improve safety further.

- Trained all workers on the site, make sure that they understand all the regulations and duties

- All workers should be alert and aware of their surrounding and operation

- The working area should have no obstacle or as less as possible

- All cranes in the operation should be inspected before the operation

- Choose the right crane for the weight of materials, overloading a crane could lead to danger

Renting a Crane with Trained Crane Signal Person

EK Crane offers crane renting service with a full team of professionals, including trained crane signal person with experience. Our service includes site survey, operation planning, and operating cranes for your construction project.Ensuring every step is carried out with the utmost care and precision

Whether you need a short-term or long-term contract, we offer both daily rental and monthly rental with all the personnels you will need. Our service focuses on mobile cranes. We have rough terrain cranes, all-terrain cranes, truck cranes and more with various sizes of cranes.

If you are interested in our service, contact LINE: @EKCRANE or the contact information below for the branch closest to your area. We offer service in every area of Thailand.

Our Branch

Bangkok-Samutprakarn Head Office

Tel. +66 2 745 9999

Location: https://maps.app.goo.gl/89scfU8K4VTUfY4W9

Rayong Head Office

Tel. +66 38 682 666

Location https://maps.app.goo.gl/CZw1JGRLGxBmfWDo9

Leam Chabang Sub-Branch

Tel. +66 38 482 666

Location https://maps.app.goo.gl/9qNV26o8LSLBSoN27

Summary of Crane Signal Person

Crane signal person is one of the vital parts of the crane operation. Their accurate communication through every type of signal whether it is hand signal or voice signal, has a great impact on the success of the operation.

The signal person is not only responsible for communicating with the crane operator, but they also helps coordinate the crew to ensure safety of the operation.The crane signal person is a crucial part that cannot be left out of the operation.

Additionally to having a signal person on site, every workers should be trained to know the meaning of the signals to ensure safety and smooth operation